Battery switch on travel trailer function is crucial for managing your RV’s power. This guide dives into how these switches work, covering various types, safe wiring practices, troubleshooting, and even advanced systems. Understanding your battery switch is key to maximizing your travel trailer’s electrical system and avoiding costly problems down the road. We’ll cover everything from basic hookups to integrating smart technology.

We’ll explore the different types of switches, like the popular 1-2-both and 1-2-off configurations, detailing their internal mechanisms and how they control power flow between your house and chassis batteries. We’ll also show you how to safely connect your batteries, emphasizing the importance of proper wiring and fuse sizing for safety and longevity.

Understanding Battery Switch Functionality in Travel Trailers

Your travel trailer’s battery switch is a crucial component, acting as the central control for your trailer’s power supply. It allows you to manage the flow of power from your trailer batteries to various appliances and systems, ensuring efficient energy use and preventing accidental drain. Understanding its function is key to maintaining your trailer’s electrical system.

Battery Switch Types

Several types of battery switches are used in travel trailers, each offering different levels of control. The most common types are the 1-2-both and 1-2-off switches. A 1-2-both switch allows you to select power from either battery 1, battery 2, or both simultaneously. A 1-2-off switch provides the same battery selection options but also includes an “off” position to completely disconnect both batteries from the trailer’s electrical system.

This is vital for preventing battery drain when the trailer is stored for extended periods. Other, less common, configurations may exist, depending on the number of batteries and the trailer’s electrical setup.

Internal Components and Operation of a Typical Battery Switch

A typical battery switch is a relatively simple electromechanical device. Internally, it consists of several heavy-duty contacts and a switching mechanism. The contacts are designed to handle the high current demands of the trailer’s electrical system. The switching mechanism, usually a rotary selector or a series of toggles, allows you to connect the batteries to the trailer’s wiring harness in the desired configuration.

The switch itself is usually housed in a robust, weatherproof enclosure to protect it from the elements. The switch operates by physically connecting or disconnecting the battery terminals to the appropriate circuit paths within the switch based on the selected position.

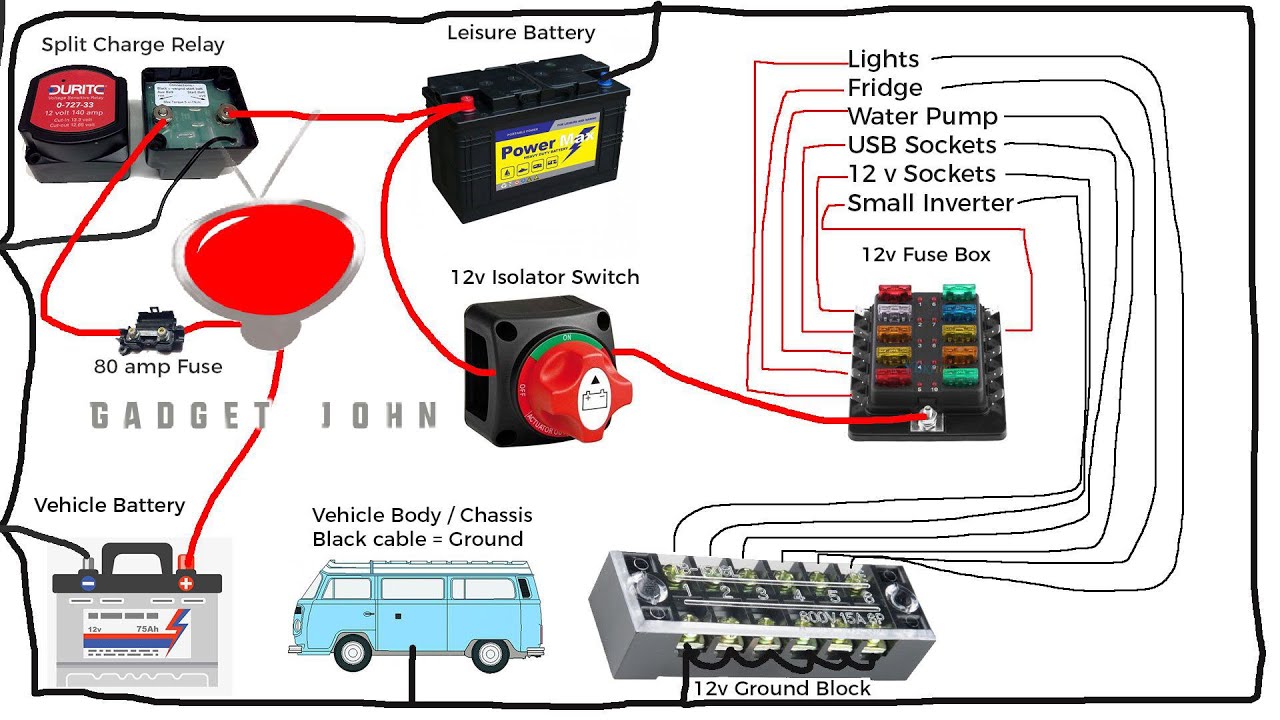

Battery Switch System Diagram

The following diagram illustrates a typical two-battery system with a 1-2-both-off switch. This configuration is common in trailers with two house batteries.

| Component | Description |

|---|---|

| Battery 1 | Provides power to the trailer’s electrical system. Typically a deep-cycle lead-acid or lithium battery. |

| Battery 2 | A second deep-cycle battery, providing additional power capacity. |

| Battery Switch | A multi-position switch controlling the power flow from the batteries to the trailer’s electrical system. Positions typically include 1, 2, Both, and Off. |

| Trailer Wiring Harness | The main wiring system connecting the battery switch to the various electrical components in the trailer. |

| Load Center/Distribution Panel | Distributes power from the battery switch to individual circuits in the trailer (lights, appliances, etc.). |

Connecting Batteries to the Switch

Connecting your batteries to a battery switch in your travel trailer is a crucial step in ensuring reliable power. This process, while seemingly straightforward, requires careful attention to detail to prevent damage to your batteries, wiring, and other components. Following these steps and best practices will ensure a safe and effective installation.

So, you’re planning a trip? Awesome! Before you jet off, remember travel insurance is key. Check out this resource for info on Aon travel insurance – it’s worth looking into their various plans. Then, to compare and really make sure you’re covered, also take a peek at another provider’s options like this one for Aon travel insurance to find the best fit for your adventure.

Don’t leave home without it!

Properly connecting your batteries to the switch involves understanding the polarity of your batteries and the wiring diagram of your chosen switch. Always double-check your connections before applying power to avoid short circuits. Using appropriately sized wires and fuses is essential for safety and preventing overheating.

Step-by-Step Battery Connection

Let’s walk through the process of connecting two 12V batteries to a typical battery switch. Remember, safety is paramount. Always disconnect the negative terminal of your batteries before making any connections.

- Identify Battery Terminals: Locate the positive (+) and negative (-) terminals on both your house and chassis batteries. These are usually clearly marked.

- Connect the Positive (+) Leads: Run appropriately sized positive cables (see wiring diagram below) from each battery’s positive terminal to the corresponding positive terminals on your battery switch. Secure connections with appropriate connectors.

- Connect the Negative (-) Leads: Run appropriately sized negative cables from each battery’s negative terminal to a common ground point. This ground point could be the chassis of the trailer or a dedicated grounding bus bar. This should NOT be connected to the battery switch. Never connect the negative cables to the battery switch itself.

- Connect the Load Leads: Connect the positive output lead from your battery switch to your house electrical system. Connect the negative lead from your house electrical system to your common ground point (as established in step 3).

- Double Check Connections: Before turning on the power, carefully inspect all connections to ensure they are secure and correctly wired. Loose connections can cause overheating and potential fire hazards.

Best Practices for Safe Wiring and Cable Management

Safe and organized wiring is crucial for both functionality and safety. Improper wiring can lead to short circuits, overheating, and potential fire hazards. Following these best practices will ensure a clean and safe installation.

- Use Appropriately Sized Wiring: Use the correct gauge of wire for the amperage of your system. Too small a gauge can overheat and potentially cause a fire. Consult a wiring gauge chart to determine the correct size.

- Secure all Connections: Use appropriate connectors and ensure all connections are tight and secure. Loose connections can create resistance, leading to overheating.

- Use Fuse Protection: Always protect your wiring with appropriately sized fuses or circuit breakers (see wiring diagram). This prevents damage to your wiring and other components in case of a short circuit.

- Cable Management: Route wires neatly and securely, using cable ties or other appropriate methods to keep them organized and prevent them from rubbing against sharp edges or moving parts.

- Use Marine-Grade Wire: For outdoor applications, use marine-grade wire designed to withstand exposure to the elements.

Wiring Diagram: Battery Switch to House and Chassis Batteries

The following table illustrates a sample wiring diagram. Remember to always consult a qualified electrician if you are unsure about any aspect of this process.

| Wire Gauge | Fuse Rating | Connection Point |

|---|---|---|

| 8 AWG | 100A | Positive (+) Battery 1 to Switch |

| 8 AWG | 100A | Positive (+) Battery 2 to Switch |

| 8 AWG | N/A | Negative (-) Battery 1 to Chassis Ground |

| 8 AWG | N/A | Negative (-) Battery 2 to Chassis Ground |

| 10 AWG | 50A | Switch Output (+) to House System |

| 10 AWG | N/A | House System (-) to Chassis Ground |

Note: This is a sample diagram. The specific wire gauges and fuse ratings will depend on your system’s amperage requirements. Always consult a qualified electrician to ensure proper sizing for your specific setup.

Importance of Appropriately Sized Fuses and Circuit Breakers

Fuses and circuit breakers are safety devices designed to protect your wiring and components from overcurrent. Using inappropriately sized fuses can lead to fire hazards. A fuse that’s too large won’t protect your wiring, while one that’s too small will blow too frequently.

For example, using a 20A fuse on a circuit drawing 30A will result in overheating and potential fire. Conversely, a 5A fuse on a circuit drawing 2A might seem safe, but it will blow unnecessarily often, interrupting power to your devices.

Always use fuses and circuit breakers rated for the correct amperage of the circuit they are protecting. Never replace a blown fuse with a higher amperage fuse.

Battery Switch Operation and Maintenance

Proper operation and regular maintenance of your battery switch are crucial for extending the lifespan of your batteries and ensuring reliable power in your travel trailer. Neglecting these aspects can lead to premature battery failure and frustrating power outages on your adventures. This section details the correct procedures and essential maintenance tasks.

Switching Between Battery Banks

Operating your battery switch is usually straightforward. Most switches have positions for “Both,” “Battery 1,” “Battery 2,” and “Off.” The “Both” position connects both battery banks in parallel, providing maximum power. “Battery 1” and “Battery 2” isolate each bank individually, allowing you to charge one while using the other or to isolate a faulty battery. The “Off” position completely disconnects both banks, preventing accidental drain.

Always refer to your specific switch’s instructions for the exact operation as labeling and functionality can vary slightly between manufacturers. Before switching, ensure your loads are appropriately disconnected to avoid any surges or damage.

Battery Switch Maintenance

Routine maintenance is key to preventing problems and ensuring your battery switch functions reliably. This involves regularly inspecting and cleaning the connections. Corrosion can build up over time, creating resistance and potentially causing overheating or even fire hazards.

Troubleshooting Common Battery Switch Problems

Several common issues can arise with battery switches. A switch that fails to switch properly might indicate a faulty switch itself or a problem with the wiring. Inspect the wiring for loose connections, corrosion, or damage. If the switch is physically damaged, it will need replacement. If the problem persists after checking wiring, the switch itself may be defective and require professional attention or replacement.

Another common issue is a constantly draining battery, even when the switch is in the “Off” position. This usually points to a problem with the switch’s internal mechanism or a parasitic drain somewhere in the wiring connected to the switch. A multimeter can be helpful in identifying the source of the drain.

Battery Switch Inspection and Maintenance Checklist

Regular inspections are vital for preventing major problems. Here’s a checklist for your routine maintenance:

- Visually inspect the switch for any signs of damage, loose connections, or corrosion.

- Clean the terminals and connections with a wire brush and baking soda solution. Thoroughly rinse and dry afterwards.

- Check for any loose wiring or frayed insulation. Repair or replace as needed.

- Test the switch functionality by switching between all positions and verifying that power is appropriately routed to each battery bank.

- Check for any unusual heating around the switch or wiring during operation. Excessive heat is a sign of a problem.

- Conduct a load test on the batteries to verify they are holding charge appropriately.

- Perform a full inspection at least twice a year, or more frequently if operating in harsh environments.

Battery Switch and Electrical System Integration

Your battery switch is the central nervous system of your travel trailer’s power, connecting your batteries to the rest of your electrical system. Understanding how it works with other components is key to avoiding problems and maximizing your power. This section will explore the interplay between your battery switch and other essential parts of your RV’s electrical setup, as well as the pros and cons of different switch configurations and crucial safety considerations.

The battery switch acts as a master control, routing power from your batteries to various systems. It interacts directly with your converter, inverter, and solar panels, determining which components receive power and when. The converter transforms 12V DC battery power to 120V AC for household appliances. The inverter does the opposite, converting 12V DC to 120V AC for running things like microwaves or coffee makers.

Your solar panels charge your batteries, and the switch manages how that power is used or stored.

Battery Switch Configurations: Single vs. Dual Battery Systems

A single battery system is the simplest setup, with one battery connected to the switch. This is sufficient for smaller trailers with minimal power demands. However, a dual battery system, using two batteries wired in parallel, offers significantly increased capacity and runtime. This is particularly beneficial for longer trips or if you frequently use power-hungry appliances.

A dual battery setup provides redundancy; if one battery fails, the other can still power essential systems. It also allows for longer periods of off-grid use before needing to recharge. However, dual battery systems require more initial investment and slightly more complex wiring.

Safety Hazards Associated with Improper Battery Switch Use and Installation

Improper use and installation of a battery switch can lead to serious safety hazards, including:

- Short circuits: Incorrect wiring can create short circuits, leading to overheating, fires, and potentially explosions.

- Electrical shocks: Working with batteries and electrical systems without proper safety precautions can result in severe electrical shocks.

- Battery damage: Incorrect switch operation can overcharge or discharge batteries, reducing their lifespan and potentially damaging them.

- System malfunctions: Improperly installed switches can lead to erratic system behavior, causing appliances to malfunction or fail.

Always follow manufacturer instructions carefully and consult a qualified electrician if you’re unsure about any aspect of the installation or operation.

So, you’re planning a trip? Awesome! Before you pack your bags, remember travel insurance is key. Check out Aon travel insurance for comprehensive coverage. They’ve got you covered for everything from medical emergencies to lost luggage. And if you want another opinion, compare their plans with the options at Aon travel insurance – sometimes a second look helps find the perfect fit for your adventure.

Don’t leave home without it!

Safely Disconnecting the Battery Switch During Extended Periods of Non-Use, Battery switch on travel trailer function

Disconnecting your battery switch during periods of prolonged non-use helps prevent parasitic drain, which is the slow discharge of your batteries due to small electrical draws from various components even when the trailer isn’t in use.

To safely disconnect, turn the switch to the “off” position. This interrupts the flow of power from the batteries to the rest of the electrical system. For additional protection, especially in areas with potential for corrosion or accidental contact, you can also disconnect the negative battery cable directly at the battery terminals. Remember to reconnect the negative cable

-before* the positive cable when reconnecting to avoid sparks.

Troubleshooting Common Issues: Battery Switch On Travel Trailer Function

So, your travel trailer’s battery switch isn’t behaving as expected? Don’t worry, it’s a common problem with straightforward solutions. This section will guide you through diagnosing and fixing the most frequent issues related to your battery switch. We’ll cover everything from simple checks to more in-depth troubleshooting.

Battery Switch Malfunction Diagnosis

A malfunctioning battery switch can manifest in several ways: no power to the trailer, inconsistent power, or even complete power failure. Before diving into complex repairs, let’s systematically check the basics. A methodical approach will save you time and frustration.

- Check the switch itself: Ensure the switch is securely in the desired position (e.g., “both,” “battery,” “off”). A loose or damaged switch can be the culprit. Try gently wiggling the switch to see if it’s making proper contact. A visual inspection for obvious damage like cracks or burnt components should also be performed.

- Verify battery connections: Loose or corroded connections at the battery terminals or at the switch itself are frequent causes of problems. Clean the terminals with a wire brush and baking soda solution, then reconnect securely. Ensure all connections are tight.

- Inspect fuses and breakers: Check both the fuses in the battery switch panel and the circuit breakers in your trailer’s electrical panel. A blown fuse or tripped breaker will interrupt power flow. Replace blown fuses with the correct amperage and reset any tripped breakers.

- Test the battery voltage: Use a multimeter to measure the voltage of each battery. A low voltage reading (below 12V for a 12V system) indicates a discharged battery that needs charging. A voltage reading of 0V indicates a dead battery.

Diagnosing Power Loss or Low Voltage

Power loss or low voltage can stem from various sources. It’s essential to systematically eliminate possibilities. Remember safety first: always disconnect the negative battery terminal before working with any electrical components.

- Check for loose wires: Carefully inspect all wiring connections related to the battery switch, paying close attention to areas prone to vibration or movement. Look for any signs of damage, corrosion, or loose connections.

- Inspect the battery cables: Examine the cables connecting the batteries to the switch for any breaks, fraying, or corrosion. A damaged cable can cause significant power loss.

- Test the switch’s continuity: Using a multimeter, check the continuity of the switch in each position. This will confirm whether the switch is properly conducting electricity.

- Load testing: If you suspect a problem with the battery itself, perform a load test to determine its capacity and health. A load test will show if the battery is able to supply the required current under load.

Identifying Faulty Wiring or Connections

Faulty wiring can be tricky to diagnose, but a methodical approach helps. Visual inspection is crucial, but using a multimeter is even more effective.

- Visual Inspection: Carefully examine all wiring for signs of damage, such as fraying, burns, or exposed wires. Pay close attention to areas where wires might rub against metal or sharp edges.

- Continuity Testing: Use a multimeter to test the continuity of each wire segment. A lack of continuity indicates a broken wire. This should be done with the power OFF.

- Voltage Drop Testing: With the power ON, use a multimeter to measure the voltage drop across each wire segment. An unusually high voltage drop indicates a problem with the wiring or a connection. A significant voltage drop across a specific wire section might point to a high resistance or a poor connection. For example, a 1-volt drop across a short, thick wire is usually acceptable, but a 5-volt drop indicates a problem.

Troubleshooting Flowchart for Battery Switch Malfunctions

This flowchart provides a structured approach to troubleshooting common battery switch issues.

- Check the switch position: Is the switch in the correct position (ON, OFF, BOTH)? If not, correct the position and test.

- Inspect battery connections: Are the battery terminals clean and securely connected? Clean and tighten connections if necessary, then test.

- Check fuses and breakers: Are any fuses blown or breakers tripped? Replace blown fuses and reset tripped breakers, then test.

- Measure battery voltage: Are the batteries adequately charged (above 12V for a 12V system)? If not, charge the batteries and test.

- Inspect wiring for damage: Are there any loose, damaged, or corroded wires? Repair or replace damaged wiring, then test.

- Test switch continuity: Does the switch conduct electricity properly in each position? If not, replace the switch.

- If problems persist: Consult a qualified RV technician.

Advanced Battery Switch Systems

Stepping up from basic battery switches, let’s explore systems offering enhanced control and monitoring capabilities. These advanced systems significantly improve battery management and provide valuable insights into your trailer’s power status. This section will cover remote control options, the integration of Battery Management Systems (BMS), and a comparison of different BMS types.

Remote Control Battery Switches

Remote control battery switches allow you to manage your trailer’s battery banks from a convenient location, often inside your RV. This eliminates the need to access the switch physically, especially helpful in inclement weather or when the switch is difficult to reach. Some systems use wireless technology, while others might use wired connections to a control panel inside the RV.

The benefits include increased convenience and improved safety by avoiding unnecessary trips outside the trailer. Features can range from simple on/off control to more sophisticated options allowing for individual bank selection and monitoring of voltage levels.

Battery Management Systems (BMS) Integration

Integrating a Battery Management System (BMS) with your battery switch provides a significant leap in battery management capabilities. A BMS monitors various parameters such as voltage, current, temperature, and state of charge (SOC) for each battery or bank. This data is crucial for optimizing battery performance, extending lifespan, and preventing overcharging or deep discharging. The BMS can automatically manage charging and discharging processes, ensuring optimal operation and preventing damage to the batteries.

The integration with the battery switch often allows for automated switching based on the BMS’s assessment of battery health and charging needs.

Types of Battery Management Systems

Several types of BMS exist, each with varying levels of sophistication and features. Simple BMS units might only monitor voltage and current, while more advanced systems incorporate temperature sensing, sophisticated algorithms for SOC estimation, and communication protocols for remote monitoring and control. Some BMS systems provide cell-level monitoring for even greater precision in managing individual battery cells within a bank.

High-end systems may include features like equalization charging to balance the charge levels of individual cells in a battery bank and prevent premature aging. The choice of BMS will depend on the type of batteries used, the complexity of the electrical system, and the level of control and monitoring desired.

Smart Battery Switch and BMS Integration Diagram

The following table illustrates a conceptual diagram of a smart battery switch integrated with a BMS and other trailer components.

| Component | Function | Connection | Notes |

|---|---|---|---|

| Solar Panels | Provide renewable energy | Charge Controller | May include MPPT for maximum power point tracking |

| Charge Controller | Regulates solar panel output | Battery Bank 1, BMS | Optimizes charging to prevent overcharging |

| Battery Bank 1 (e.g., Lithium) | Primary power source | BMS, Smart Battery Switch, Inverter | Example: 12V Lithium-ion battery bank |

| Battery Bank 2 (e.g., Lead-Acid) | Secondary power source | Smart Battery Switch | Example: 12V Lead-acid battery bank for starting |

| BMS (Battery Management System) | Monitors and protects Battery Bank 1 | Battery Bank 1, Smart Battery Switch, Control Panel | Provides real-time data and safeguards against overcharging/discharging |

| Smart Battery Switch | Selects and manages power flow | Battery Bank 1, Battery Bank 2, Load Center | Remotely controllable and BMS-integrated |

| Inverter | Converts DC to AC power | Battery Bank 1 | Supplies AC power to appliances |

| Load Center | Distributes power to appliances | Smart Battery Switch | Protects circuits with breakers/fuses |

| Control Panel (Inside RV) | Displays BMS data and controls the Smart Battery Switch | BMS, Smart Battery Switch | Provides user interface for monitoring and control |

Mastering your travel trailer’s battery switch isn’t just about flipping a lever; it’s about understanding the heart of your RV’s electrical system. By following safe practices, performing regular maintenance, and knowing how to troubleshoot common problems, you’ll ensure reliable power for all your adventures. From basic operation to advanced systems, this guide provides the knowledge to keep your RV running smoothly and efficiently, maximizing your off-grid experience.

FAQ Corner

What happens if I leave my battery switch in the “off” position?

Leaving the switch off completely disconnects both batteries from the trailer’s electrical system, preventing any power drain. This is ideal for long-term storage.

Can I use a battery switch with different battery types (e.g., lead-acid and lithium)?

Generally, it’s best to use a battery switch with similar battery types. Mixing types can lead to compatibility issues and potentially damage your batteries or system.

How often should I check my battery switch connections for corrosion?

Inspect your connections at least twice a year, or more often if you live in a humid climate. Clean any corrosion immediately to prevent problems.

My battery switch is making a clicking noise. What could be wrong?

A clicking noise often indicates a problem with the switch itself or a low battery voltage. Check your battery voltage and the switch for any damage.